Etp Plant

Product Details:

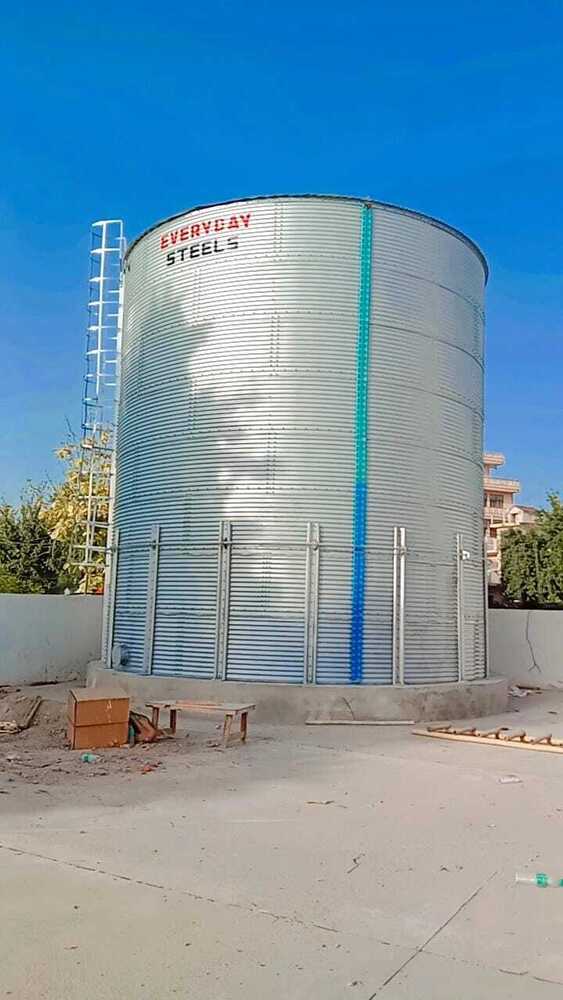

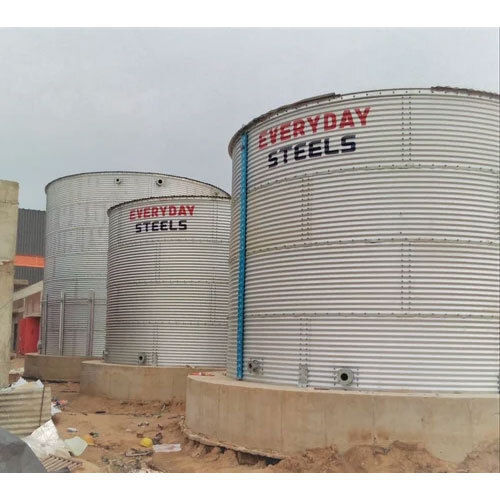

- Usage Residential & Commercial Building

- Color Silver

- Size Different Size Available

- Condition NEW

- Product Type Etp Plant

Etp Plant Price And Quantity

- 300000.0 INR/Unit

- 1 Unit

Etp Plant Product Specifications

- Residential & Commercial Building

- Different Size Available

- Etp Plant

- Silver

- NEW

Etp Plant Trade Information

- Cash in Advance (CID) Cheque

- 15-20 Days

- Yes

- Complete Packaging

- Asia

- All India

- ISO

Product Description

The design and construction of these tanks are critical for the efficient operation of an ETP. Materials must be selected based on the chemical properties of the effluent to prevent corrosion and ensure durability.

An Effluent Treatment Plant (ETP) is designed to treat industrial wastewater to meet environmental standards before discharge or reuse. Central to this process are various tanks, each serving a specific function:

-

Collection Tank: Receives and stores raw effluent from the industrial process. This tank ensures a steady flow to subsequent treatment stages.

-

Equalization Tank: Balances fluctuations in effluent flow and composition. By maintaining consistent conditions, it optimizes the performance of downstream treatment units.

-

Aeration Tank: Facilitates the biological treatment of wastewater by introducing air or oxygen, promoting the growth of microorganisms that degrade organic pollutants.

-

Clarifier Tank: Allows treated water to settle, separating sludge from the effluent. The clarified water is then suitable for discharge or further treatment.

-

Sludge Holding Tank: Collects and stores the sludge removed during the treatment process. This sludge is later subjected to dewatering, digestion, or other disposal methods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+